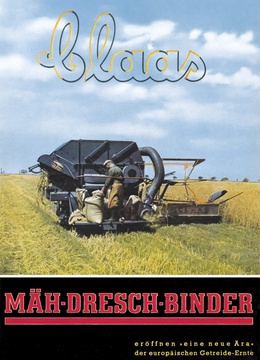

1913 - The beginning

In 1913 efforts at CLAAS were focused on installing knotters on hay balers of other manufacturers. The operational reliability of these knotters declined with the ever-deteriorating twine quality during World War I. August Claas succeeded in improving the existing knotters in such a way that they could cope even with poorer-quality twine.