New High Performance Coulters

Published on 04 February 2021

AMAZONE’s new six-metre Cirrus 6003-2 and 6003-2C seed drills are now available with high performance TwinTeC+ double disc coulters that enable precise and rapid sowing of large areas.

CLAAS Harvest Centre General Manager - Product, Tim Needham, says the new coulters incorporates several technical innovations.“TwinTeC+ coulters provide reliable operation under all soil types and operating conditions,” he says.

“They cut perfect seed furrows with accurate depth at operating speeds of between 10 and 20 km/h.”

The 380 mm diameter coulters are made of pre-tensioned boron steel for high wear resistance. They are fitted on a row spacing of 12.5 cm (5”) and 16.6 cm (6.5”).

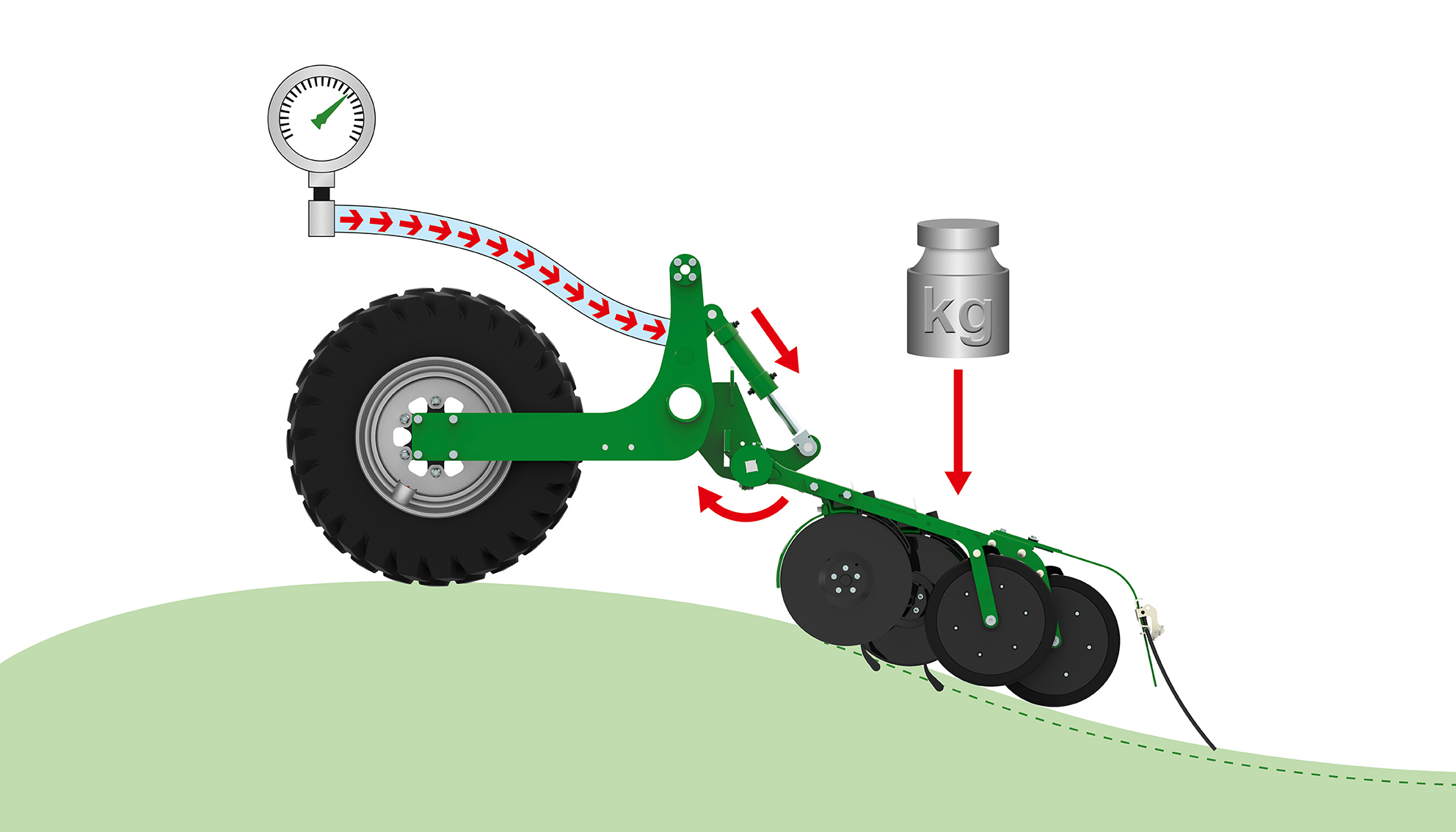

Coulter pressure can be hydraulically adjusted from 15 to 100 kg to ensure accurate contour tracking on hilly terrain and precise seed placement, even with small seeds. “This means coulter pressure can be quickly and easily matched to changing soil conditions to maintain consistent depth guidance,” Tim says.

“Even with crusted surfaces, heavy soils or undulating ground, the coulter reliably reaches the placement depth.

“The wide spacing between coulters and rows, together with the relatively flat 10-degree pitch of the seeding discs, ensures very good throughput and blockage-free operation, even under different conditions.”

Coulter pressure can be adjusted using the pressure relief valve, while working depth is adjusted using the mechanical crank handles. Depth guidance rollers with running widths of 50, 65 or 80 mm can be fitted to match to light, medium or heavy soil conditions.

A coulter harrow with adjustable operating intensity can be fitted to the wheel carriers of the second coulter row. Alternatively, the Cirrus can be equipped with the existing RoTeC single disc coulters, which are ideal for use on heavy or sticky soils or if there is a high amount of crop residues.

The coulter arm, manufactured from forged steel, thickens at the end and is interlocked with tongue and groove, thereby creating a longer and stronger welding seam. The coulters are attached to the machine frame via a special bearing clamp made of high-strength forged steel.

Embossing on the inside of the clamp prevents the four shock-absorbing rubber cords from moving or twisting. A metal stop prevents the coulter arm from swinging up during road transport.

The disc carrier arms also carry a guide extension, that prevents the seed from jumping within the furrow; a closer that presses the seed into the bottom of the furrow for uniform placement and crop emergence; and a flexible plastic or optional metal disc scraper.

Tim says the coulters incorporate numerous time-saving design features that minimise wear and make maintenance easy. “For example, the mounting bolts for the disc carrier arms are not threaded into the body,” he says.

“Instead, they are mounted using bolts whose nuts are seated within the frame.

“In the unlikely event that an overload causes one of the bolts to break, you can simply knock the nut out with a mandrel.

“Likewise, the PVC seed supply lines can be easily replaced by loosening a single bolt.

“Little things, like the coulters having a dolly that allows you to loosen the bolts in the coulter bearing, can save hours.”