CLAAS Makes the Connections

Published on 03 July 2020

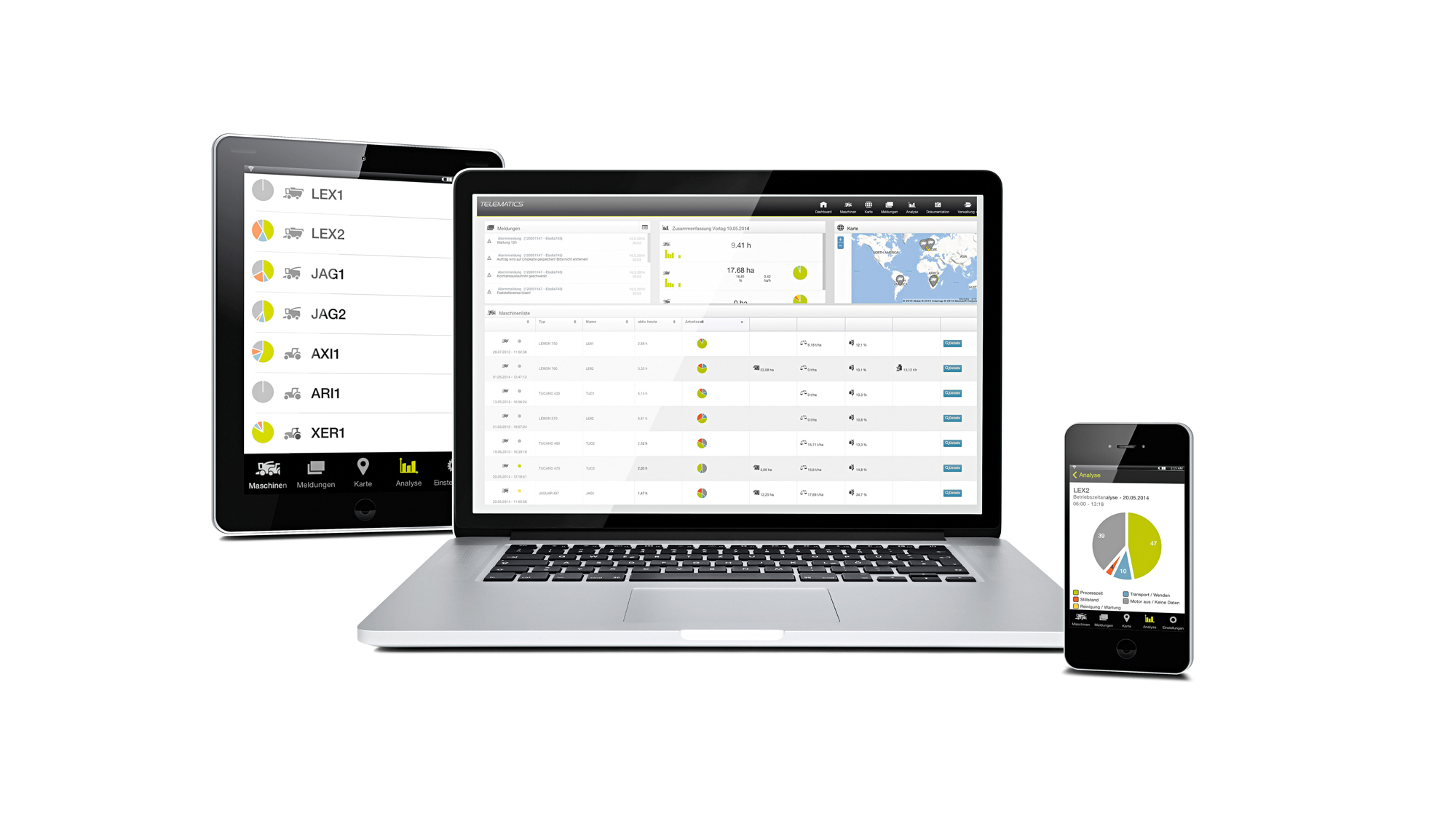

CLAAS has upgraded its TELEMATICS remote monitoring technology to include automatic documentation, data transfer and mixed-fleet monitoring.

TELEMATICS continuously transfers GPS location, machine performance and yield data from connected CLAAS combine harvesters, forage harvesters and tractors via the mobile phone network. The technology can also be fitted to a range of CLAAS implements, including QUADRANT large square balers and CARGOS dual-purpose wagons.

CLAAS Harvest Centre General Manager of Product, Tim Needham, says TELEMATICS enables authorised individuals to monitor the location, machine performance and yield data of equipped machines in real time from any location. “This technology provides enormous benefits in terms of logistics, service and data,” he says. “For example, this data can be used to determine where transport is required, produce accurate job data or create precise yield maps.

“Australian grain producers are quite familiar with yield mapping.

“The powerful combination of TELEMATICS and the NIR sensor fitted to CLAAS JAGUAR forage harvesters means producers and agronomists can now produce yield maps for forage crops as well.

“The NIR sensor accurately measures yield and quality, including dry substance content and also about constituents such as sugar, starch, protein and fibre content.

“The amount of silage inoculant applied can also be documented.

“TELEMATICS also allows dealerships to provide remote diagnostics services, which means machinery can be serviced proactively and technicians arrive with all the parts they need to complete the job with minimal downtime.”

Collected work and yield data can now be shared with many well-known farm management systems, including 365FarmNet, Cropio, Trimble, CLIMATE FieldView, OMNIA, mySOYL, SEGES CROPMANAGER, MyEasyFarm and Biogaspower (LivingLogic) using the new CLAAS API interface.

“This interface allows two-way sharing,” Tim says.

“Field boundaries are automatically transferred to the TELEMATICS platform and conversely, machine and field data are automatically transferred back to the farm management system.

“The system is fully automated, so there’s no additional work for the driver or in the office.

“Alternatively, data can be exported and transferred in ISOXML format if required.”

The ISOBUS interface can also be used to transfer data from stored add-on devices such as balers or loader wagons.

Another new development is the introduction of DataConnect, the award-winning platform presented at last year’s Agritechnica, which enables TELEMATICS to monitor mixed fleets of CLAAS, Case IH, John Deere and New Holland machinery.

- 2: CLAAS TELEMATICS now includes time-saving automatic documentation of machine data and agronomic information.

- 3: TELEMATICS, in combination with the NIR sensor fitted to CLAAS JAGUAR forage harvesters, enables yield mapping of forage crops.

4: TELEMATICS can now be used to monitor mixed fleets of CLAAS, Case IH, John Deere and New Holland machinery.